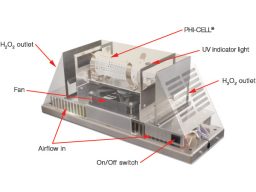

ACTIVE Air Transit Air Purification System

The ACTIVE Air system utilizes RGF’s patented Photohydroionization® (PHI-CELL®) technology to substantially reduce airborne and surface bacteria, viruses, odors, mold and VOCs (chemical odors). ACTIVE Air with UV-PHI® is designed and certified for public transit and transportation related applications.

| MODEL # | REPLACEMENT CELL | Volts | Watts | |

|---|---|---|---|---|

| 81G53015-12VD | Call for Part # | 12 VDC | 12 | Call for info. |

- Details

- Features & Benefits

- Applications

- Technical Specs

- Certifications

Designed and certified for installation on transit vehicles and trains, ACTIVE Air quietly circulates air around the space while creating and distributing low-level airborne hydrogen peroxide (H2O2). Testing shows significant reductions in viruses, bacteria, mold, and odor within minutes of operation, resulting in safe, clean air within the treated space.

Why Use RGF’s Photohydroionization® Technology?

Photohydroionization® (PHI) is an active air treatment technology. Active air treatment is the process of reducing air and surface contaminants by recreating safe, natural levels of hydrogen peroxide (H2O2) in occupied areas.

RGF's patented PHI-CELL® technology combines a photocatalytic process and a multiwavelength UV source to create active air purification. The combination of UV light and a hydrated quad-metallic catalyst drives a reaction that produces low level, airborne H2O2. RGF's PHI-CELL® air treatment systems are operating safely in over four million installations globally.

• Capable of reducing airborne and surface bacteria, viruses, odors, mold and VOCs (chemical odors)

• Economical

• Wall mountable

• Minimal maintenance

• Lightweight

• Compact

• Transit Bus

• School Bus

• Rail

• Motor Coaches

Scroll

Scroll| Model # | 81G53015-12VD |

|---|---|

| Volts | 12 VDC / 24 VDC |

| Technology | PHI-CELL® |

| Watts | 12 W |

| Material | Stainless steel Housing |

| Dimensions | 6.25” H x 6.25” D x 18” W |

| Ship Weight | 5 lbs. |

| Controls | On/Off Switch |

| Approximate Coverage Area | 1,000 Sq. Ft. |

| Warranty | 1 year (U.S. only) |

• IEC 61373: 2010 Rolling Stock equipment – Shock and vibration

• IEC 62236-3-2 (IEC 60571:2012): Electronic Equipment Used on Rolling Stock

• IEC 61000: All applicable elements (Electromagnetic Compatibility (EMC), Emissions Standard for Industrial Environments, etc.)

• FCC 47CFR Part 15, CISPR 25: Unintentional Radiators

• CISPR 16/IEC 60571-6-4: Emissions

• SAE J1455: All applicable elements (Thermal Cycling 24hr, Temperature Shock, Humidity, Operational & Crash Shock, etc.)

• SAE J1113: All applicable elements (Coupled immunity, ESD, Radiated electromagnetic fields, etc)

• EN 50155: All applicable elements (Low temp startup, dry heat test, etc.)